6-Sept-2003 Bill Webster, Master machinist, finished the cylinder saddle for me. He does incredible work--the cylinder holes are perfectly parallel to each…

6-Sept-03 The cylinder saddle is all finished, holes drilled and tapped. The cast iron liners have been pressed in place inside the bored cylinder holes. The…

6-Sept-03 Bottom view of the cylinder saddle. The frame will bolt to the inside of the piston cylinders. It looks like the castings are mismatched in the…

Drilling a very tiny hole for the oil like. 'We don't have any 3-48 taps' Bill says, leaving me to hand tap it later.

In the Summer of 2003, Bill W., took the rough milled cylinder saddle halves and machined them for me. Here, on one of many angle plate setups, he cuts the…

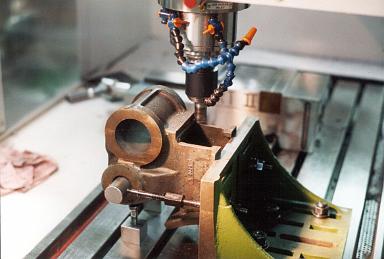

Summer 2003 - Bill W., runs a bolt circle program in a CNC mill to drill and tap the cover mounting holes.

Summer 2003 - CNC machines are nice, if you have them. Here Bill W., has drill and is now tapping the cylinder joining half.

Summer 2003 - Bill W. bores the piston cylinder out with a precision bore on yet another angle plate setup.

Summer 2003 - Bill W. drills the exhaust ports on the inside of the saddle in a complex (for me) work holding setup.