A small locomotive - 'The Crab' - The first locomotive out of the Neidrauer Shops

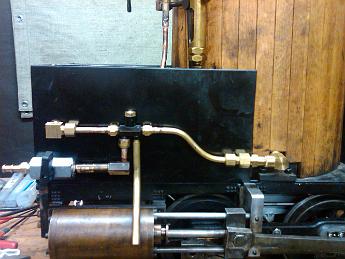

A small locomotive - 'The Crab' - The first locomotive out of the Neidrauer Shops2018: Installed new exhaust pipes because the old steel ones developed leaks. 2011: The modified grease fittings work great! The Crab has some lettering on it (NYC), the riding car is working fine and the new NYC Gondola works well as a two person passenger car. Time to burn some more coal! Winter 2011 - The Crab is readied for the summer season. We are experimenting with modified grease fittings as cylinder cocks. August 2010 - a mild overhaul was completed. Pulled the cab, bunker, boiler and chests, remade the ash pan, eliminated the troublesome axle pump, added a new handpump and steam injector. May 2010 - The water pump ram is jamming in the pump bore, causing the wheels to lock up. It will be replaced with an injector. Also the graphite string piston rings will be replaced because they are leaking. August 2009 - Improvements to the water pump and riding car made. *** November 2008 It's Done It Runs!! *** First steam up ever during the Thanksgiving holiday and it ran great! I am so happy!

Page 2 of 2